Saintyol DAWIN Machinery tells you the preocautions for concrete pumping

sourceSaintyol DAWIN News Center

publisherJenny

time2022/08/01

- Precautions for pump operation:

1. The place where the pump truck is in place is flat and solid, and there are no obstacles around. Pump trucks must not be parked on slopes. The parking position meets the needs of pouring, and does not obstruct each other with other on-site machinery, which affects the construction progress and the safety of construction workers.

Precautions for pump operation:

1. The place where the pump truck is in place is flat and solid, and there are no obstacles around. Pump trucks must not be parked on slopes. The parking position meets the needs of pouring, and does not obstruct each other with other on-site machinery, which affects the construction progress and the safety of construction workers.

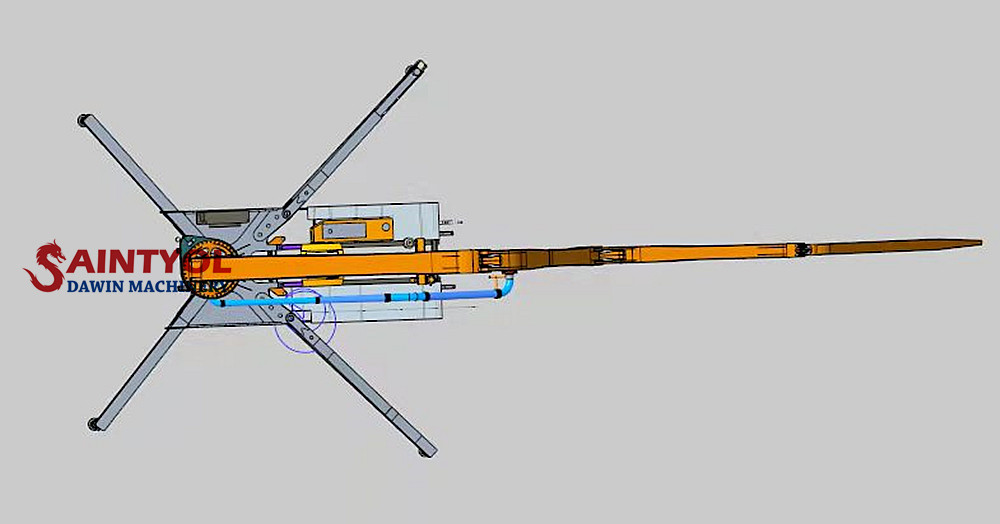

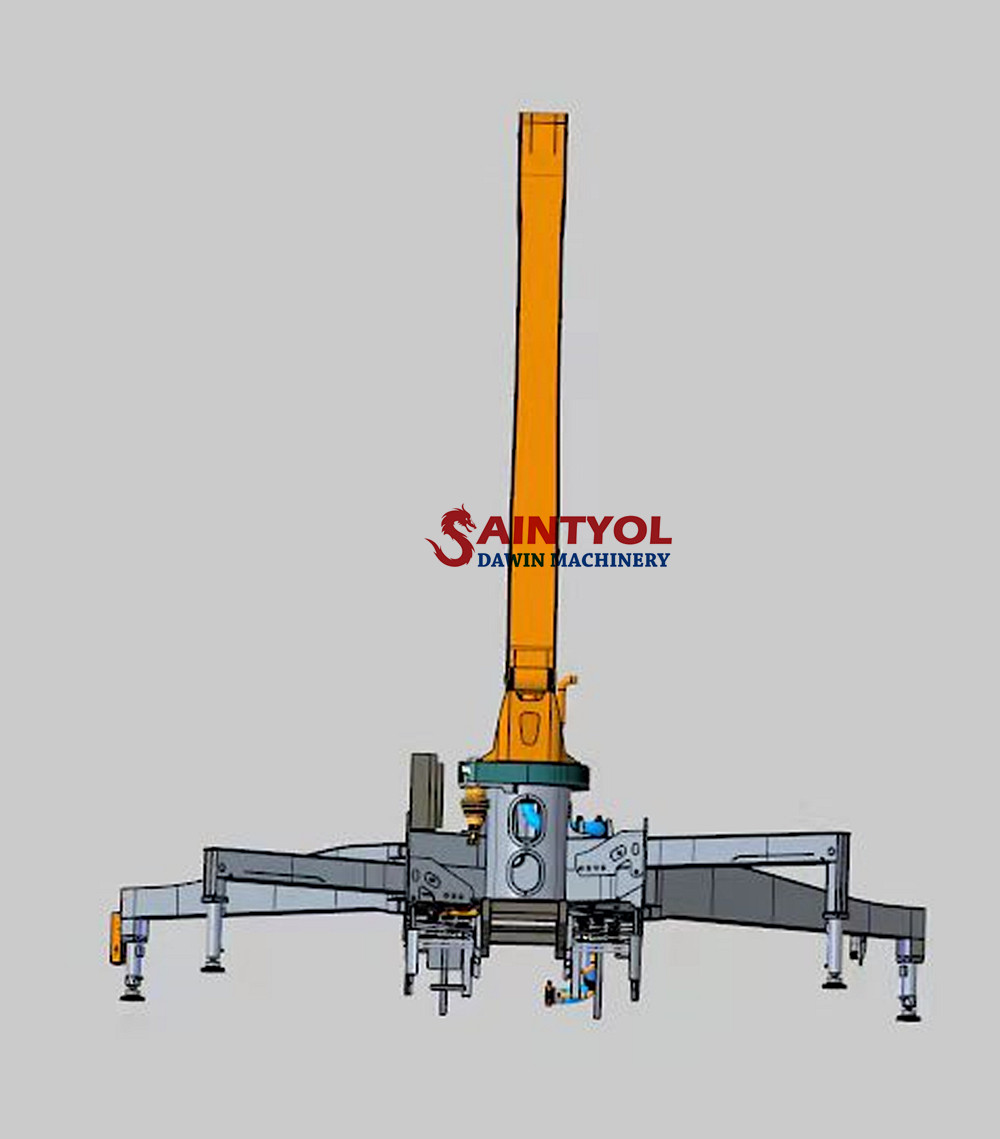

2. After the pump truck is in place, set up the outriggers and keep the body level and stable. When feeding materials with the placing boom, the body inclination should not be greater than 3°.

3. After being in place, the pump truck should turn on the parking lights to avoid collision.

4. The inspection items before operation meet the following requirements:

1. Sufficient addition of fuel, lubricating oil, hydraulic oil and water tank, tire pressure in compliance with regulations, lighting and signal indicators are complete and good;

2. The hydraulic system works normally, and the pipeline has no leakage; the clean water pump and equipment are in good condition;

3. There is no debris in the mixing hopper, and the protective grid on the hopper is intact and tightly covered;

4. The conveying pipeline is firmly connected and sealed well.

5. The pipes and hoses used for the distribution pipe shall not use pipes with a diameter exceeding the specified diameter, and the connected hoses shall be fastened with anti-fall safety belts.

6. Extending the boom should be carried out according to the order of the factory manual, and the boom can only be rotated after it is lifted from the bracket. It is strictly forbidden to use the boom to lift or drag objects. When pouring concrete, be careful not to collide with the drilling rig and gantry crane.

7. When the boom is fully extended, do not move the body. When the body needs to be moved during the operation, the upper boom should be folded and fixed, and the moving speed should not exceed 10km/h.

8. During the work, pay attention to the command of the staff at the pouring point, and suspend or start the pouring operation in time.

9. Do not drag the hose at the front end of the boom on the ground; it is strictly forbidden to extend the distribution piping and boom. When the wind is at level 6 and above, the placing boom shall not be used to transport concrete.

10. Before pumping, when the hydraulic oil temperature is lower than 15℃, use the method of prolonging the idle running time to increase the oil temperature.

11. When pumping, check the operation of the pump and the stirring device, monitor the instruments and signal indicators, and stop the machine in time if any abnormality is found.

12. The concrete in the hopper should be kept above the centerline of the mixing shaft.

Thirteen, pumping concrete should be continuous operation. When it is forced to suspend due to interruption of feeding, the mixing bucket keeps part of the concrete, and pumps part of the concrete at regular intervals to prevent the concrete in the pipe from segregating or solidifying.

14. During the operation, the grid in the hopper shall not be removed, and the unqualified aggregate or sundries shall be cleaned up in time.

15. During pumping, when it is found that the pressure is expressed to a high value and the running sound changes, the pumping shall be stopped immediately, and the reverse operation method shall be adopted to eliminate the blockage of the pipeline; when it is invalid, the pipe shall be disassembled for cleaning.

16. After the operation, output all the concrete in the pipes and hoppers, and then flush the hoppers, pipes, etc. When using compressed air to clean the pipeline, it is strictly forbidden to stand within 10m in front of the outlet end of the pipeline.

17. After the operation, do not use compressed air to flush the piping of the distribution boom, and the folding and shrinking of the distribution piping shall be carried out in the specified order.

18. After the operation, reset the operation switches, adjustment handles, handwheels, operating levers, cocks, etc. of various parts, and the hydraulic system