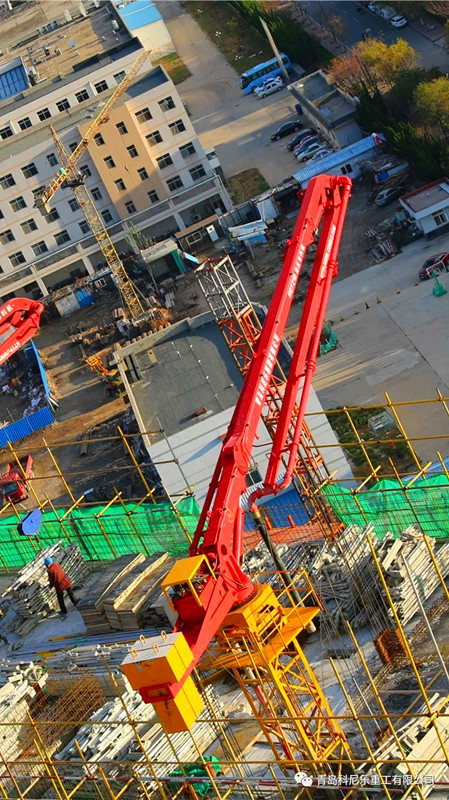

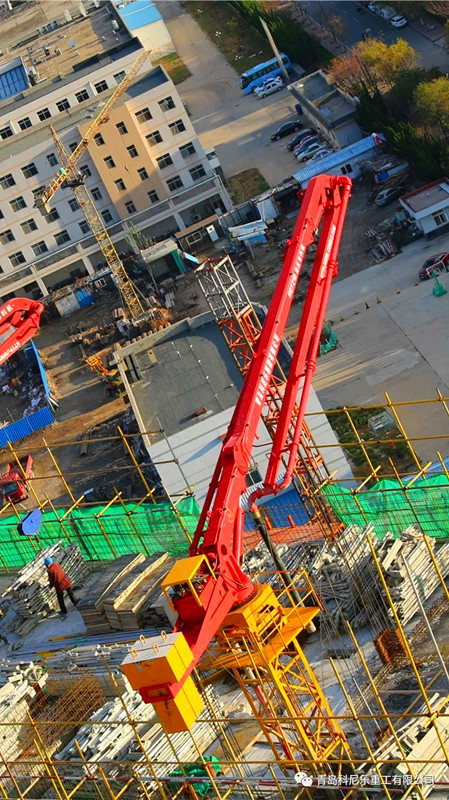

Do these four things, keep away from blocking concrete pump placing boom pipelines

sourceSaintyol DAWIN News Center

publisherJenny

time2021/11/23

- In the concrete pumping construction operation, once the pipe blockage occurs, the slight blockage can be dredged by repeated forward and reverse pumps and tapping with a wooden hammer. Serious blockage may need to be removed and replaced. Therefore, prevention of pipe blockage is particularly important.

In the concrete pumping construction operation, once the pipe blockage occurs, the slight blockage can be dredged by repeated forward and reverse pumps and tapping with a wooden hammer. Serious blockage may need to be removed and replaced. Therefore, prevention of pipe blockage is particularly important.

Point one

In order to ensure the continuity of pumping concrete operation and ensure the quality of concrete pouring, the interval between operations should not be too long to prevent blockage. If the interval is longer for some reason, the pump should be started every 5 to 10 minutes or forward and reverse pump several times to prevent blockage.

Point two

The pumped concrete should be designed in strict accordance with the pumping concrete regulations to strictly control the slump.

Point three

The selected aggregate particle size must meet the requirements, and generally should not be greater than 1/4 of the diameter of the conveying pipe.

Point four

Before pumping the concrete, clean water should be used to lubricate the pipes, and the mortar should be sent first, and then the concrete should be sent to prevent clogging.