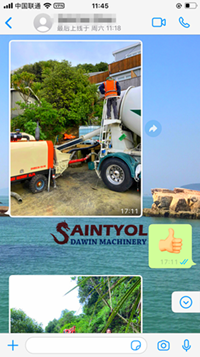

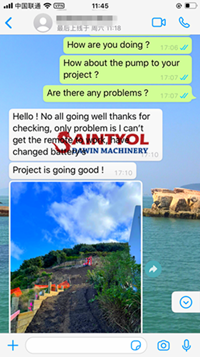

Saintyol DAWIN 30m3/hr diesel concrete pump works in New Zealand projects

sourceSaintyol DAWIN News Center

publisherJenny

time2021/08/02

- Saintyol DAWIN 30m3/hr diesel concrete pump works in New Zealand projects , DXBS30-11-56 diesel concrete pump well done construction works in New Zealand for high land constructions

Saintyol DAWIN 30m3/hr diesel concrete pump works in New Zealand projects , DXBS30-11-56 diesel concrete pump well done construction works in New Zealand for high land constructions

Small concrete pump is a kind of machine, which is used to convey concrete continuously along the pipeline. And it has played an essential role in conveying concrete. Under the current circumstance of sluggish economy, big city commercial housing construction, railway construction, bridge construction are in frustration, therefore, the small mobile concrete pump is in great demand. And small concrete pumps are widely used to convey mortar, small aggregates, refractory materials, thermal insulation materials, greening soil in ecological environment construction and plain concrete, fiber concrete in various kinds of engineering projects.

XBS, DXBS series of products is the mortar transportation equipment specially developed for the features of floor heating construction, suiting for fine aggregate concrete filled layer during floor heating engineering or the large area and high efficiency construction of mortar filling layer. XBS series products are also suitable for all types of construction projects in the transport of fine stone concrete, refractory, insulation materials transportation, the transportation of green soil in the ecological environment construction and pressure grouting of various foundation piles.

XBS-series fine stone pump have transformed from the original Φ80 delivery tube to Φ100 delivery tube, which can transport the <3cm concrete, so XBS-series fine stone pump has more versatile function. (like transport mortar, fine stone and large aggregate concrete).

Electronic control system: High degree of automation and reliability, major appliances adopts Schneider, LS.

Lubrication system: Adopting the automatic multi-point lubrication technology featuring one to one lubrication, with better efficiency and the extending service life of wearing parts.

Hydraulic system: The new application of liquid control reversing technology makes pumping more reliable and lower failure rate in the hydraulic system. It can configures the valve specially manufactured for the liquid control system, features with large flow and have lower power and less impact and longer life.

The main oil pump: Adopts the constant power variable plunger pump of the joint venture brand, so that the constant power control could effectively prevent motor and diesel overload and could withstand higher pressures and loads than conventional gear pump, so as to ensure the system running smoothly and reliably, the overpressure relief function can effectively protect the main pump and the diesel engine.

Power system: The electric fine stone pump adopts the well-known domestic and foreign brands: Yantai motor, Siemens Beide motor, the fine stone pump of diesel engine adopts low-power high-efficiency Tianjin Lovol, Yuchai.

Hopper device: Increased volume, added the fence, equipped with vibration motor, to meet the requirements of fine concrete pumping.

Cooling system: Adopts the air-cooled, water-cooled twin cooling system, which not only adjusts to the cold climate, but effectively controls the hydraulic oil temperature so as to ensure the safety and reliability of equipment operation.

Hydraulic pipe fittings: The hose is imported from Italy and the joint is the US Eaton products, the hose connector assembly sets is provided by Eaton, aiming to ensure the safety of the hydraulic system.

S valve: Adopts the manganese steel overall casting and the wearing surface adopts wear-resistant materials featuring the dual advantages of pressure and abrasion resistant. Lumen transition is smooth, providing with unimpeded flow of concrete, so that the pumping performance has been further improved.

,: , .

Glasses plate: The cutting loop was made by cemented carbide with durable service.

Glasses plate cutting loop: Glasses plates and cutting loop inlaid adopts the carbide hard to ensure a durable design.

The features and advantages of the full hydraulic control hydraulic system:

Extending component life: Adopts full hydraulic control reversing hydraulic systems, pumping, S tube is assigned to the alternate action without involving in the electrical signal with less reversing impact and lower noise and can significantly improved the service life of hydraulic pump and hydraulic valve.

Improving equipment reliability: Full hydraulic control system eliminates the intermediate links of electrical control signal and the move greatly improves the reliability of the entire equipment.

Reducing the failure frequency: The full hydraulic control system adopt the centralized valve plate, puts the main hydraulic valve system to the valve plate and reduces pipe cross-connect, so that the system becomes more compact and lows leakage chances.

Lowering maintenance costs: The system deletes the four most easily damaged components in the electric control commutation system and reduces the maintenance costs of the equipment.

XBS-series fine stone pump have transformed from the original Φ80 delivery tube to Φ100 delivery tube, which can transport the <3cm concrete, so XBS-series fine stone pump has more versatile function. (like transport mortar, fine stone and large aggregate concrete).

Electronic control system: High degree of automation and reliability, major appliances adopts Schneider, LS.

Lubrication system: Adopting the automatic multi-point lubrication technology featuring one to one lubrication, with better efficiency and the extending service life of wearing parts.

Hydraulic system: The new application of liquid control reversing technology makes pumping more reliable and lower failure rate in the hydraulic system. It can configures the valve specially manufactured for the liquid control system, features with large flow and have lower power and less impact and longer life.

The main oil pump: Adopts the constant power variable plunger pump of the joint venture brand, so that the constant power control could effectively prevent motor and diesel overload and could withstand higher pressures and loads than conventional gear pump, so as to ensure the system running smoothly and reliably, the overpressure relief function can effectively protect the main pump and the diesel engine.

Power system: The electric fine stone pump adopts the well-known domestic and foreign brands: Yantai motor, Siemens Beide motor, the fine stone pump of diesel engine adopts low-power high-efficiency Tianjin Lovol, Yuchai.

Hopper device: Increased volume, added the fence, equipped with vibration motor, to meet the requirements of fine concrete pumping.

Cooling system: Adopts the air-cooled, water-cooled twin cooling system, which not only adjusts to the cold climate, but effectively controls the hydraulic oil temperature so as to ensure the safety and reliability of equipment operation.

Hydraulic pipe fittings: The hose is imported from Italy and the joint is the US Eaton products, the hose connector assembly sets is provided by Eaton, aiming to ensure the safety of the hydraulic system.

S valve: Adopts the manganese steel overall casting and the wearing surface adopts wear-resistant materials featuring the dual advantages of pressure and abrasion resistant. Lumen transition is smooth, providing with unimpeded flow of concrete, so that the pumping performance has been further improved.

,: , .

Glasses plate: The cutting loop was made by cemented carbide with durable service.

Glasses plate cutting loop: Glasses plates and cutting loop inlaid adopts the carbide hard to ensure a durable design.

The features and advantages of the full hydraulic control hydraulic system:

Extending component life: Adopts full hydraulic control reversing hydraulic systems, pumping, S tube is assigned to the alternate action without involving in the electrical signal with less reversing impact and lower noise and can significantly improved the service life of hydraulic pump and hydraulic valve.

Improving equipment reliability: Full hydraulic control system eliminates the intermediate links of electrical control signal and the move greatly improves the reliability of the entire equipment.

Reducing the failure frequency: The full hydraulic control system adopt the centralized valve plate, puts the main hydraulic valve system to the valve plate and reduces pipe cross-connect, so that the system becomes more compact and lows leakage chances.

Lowering maintenance costs: The system deletes the four most easily damaged components in the electric control commutation system and reduces the maintenance costs of the equipment.