Common classification of wet concrete spraying machine

sourceSaintyol DAWIN News Center

publisherJenny

time2020/12/28

- Concrete wet spraying machines have become the mainstream equipment for concrete spraying. Common concrete wet spraying machines are generally divided into hydraulic wet spraying machines, rotor wet spraying machines, and vehicle-mounted wet spraying machines. Wet spray concrete machine has the advantages of high construction efficiency, stable construction quality, strong construction safety, and good construction environment. It is widely used in wet spray concrete construction operations

Concrete wet spraying machines have become the mainstream equipment for concrete spraying. Common concrete wet spraying machines are generally divided into hydraulic wet spraying machines, rotor wet spraying machines, and vehicle-mounted wet spraying machines. Wet spray concrete machine has the advantages of high construction efficiency, stable construction quality, strong construction safety, and good construction environment. It is widely used in wet spray concrete construction operations in mines, tunnels, culverts, subways, hydropower projects, underground projects and slope protection.

1. Hydraulic wet spraying machine

The hydraulic wet spraying machine is a pumping concrete wet spraying machine, which adopts hydraulic pumping type, with high system reliability and stable delivery. Continuous adjustment of the shotcrete volume: The main oil pump adopts a variable plunger pump, and the injection speed can be adjusted freely. The addition amount of accelerator is continuously adjustable: it can be adjusted steplessly according to the shotcrete amount.

2. Rotor wet spraying machine

The rotor wet spraying machine is a rotor piston concrete wet spraying machine, using a mature rotor piston cam feeding mechanism, stable performance, convenient operation and maintenance, and long service life. The three cavities are fed radially at the same time, realizing uniform and thin flow transportation in the plastic concrete pipeline. Adopting anti-sticking technology, the piston in the machine is forced to pump and feed, which solves the problem of sticking in the material cavity.

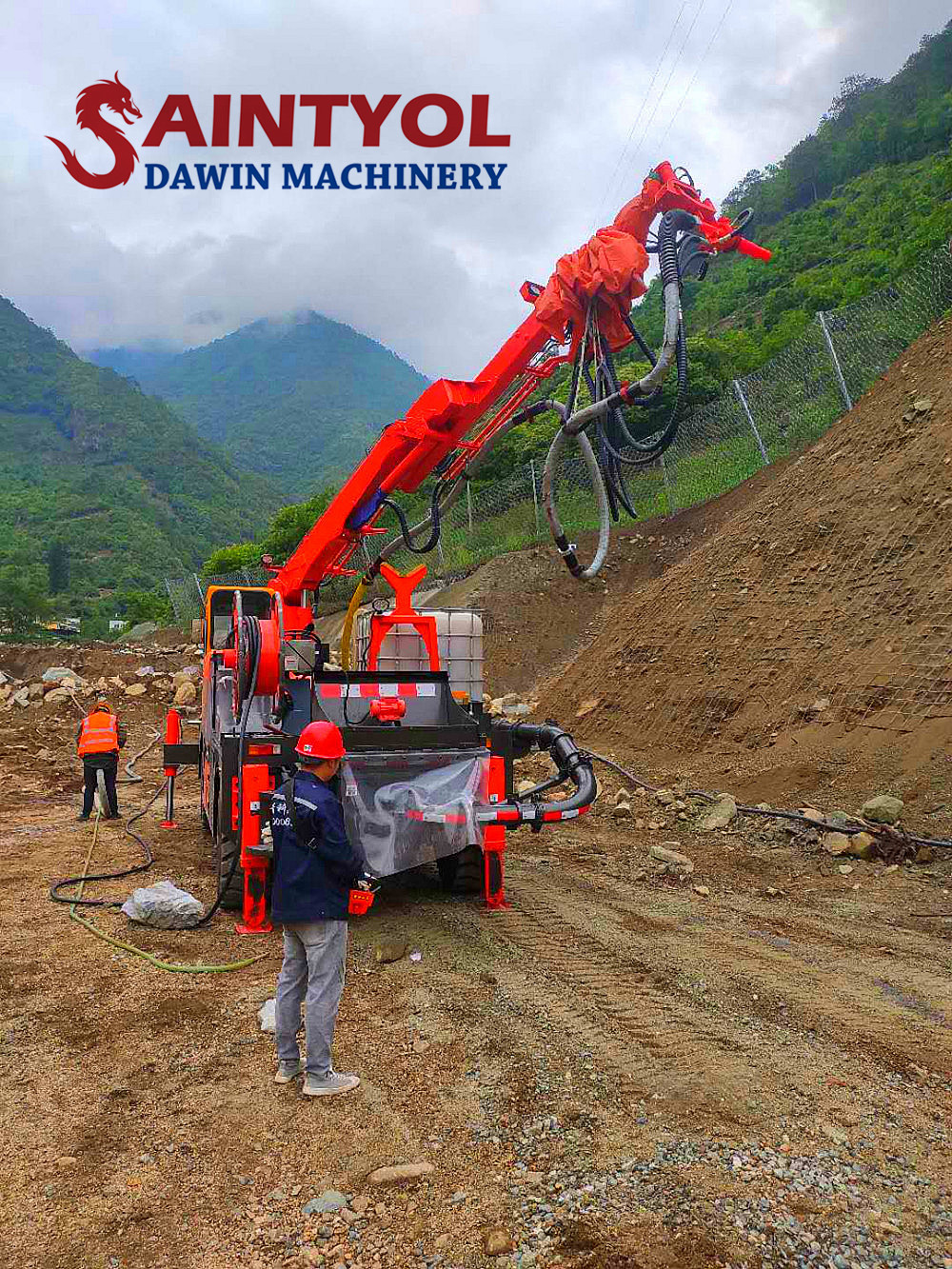

The vehicle-mounted wet spraying machine adopts the automobile chassis, the parts are universal, and the equipment is easy to maintain. The spray system adopts single nozzle or double nozzle spraying operation, and the construction efficiency is high. The vehicle-mounted wet spraying machine solves the shortcomings of the traditional small wet spraying machine that can not meet the concrete spraying of long and large tunnels, improves the working environment of the concrete spraying workers inside the tunnel, improves the construction efficiency, reduces the concrete consumption, and effectively guarantees the construction quality. Lower carbon emissions, more in line with the concept of environmental protection.