How to use wet sprayer wet concrete spraying machine?

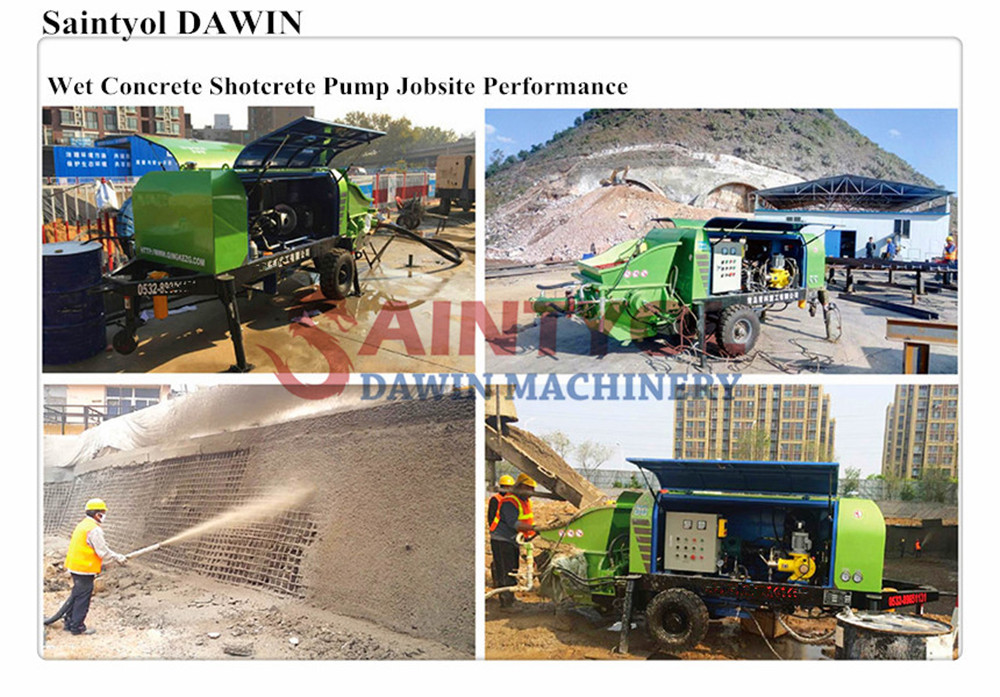

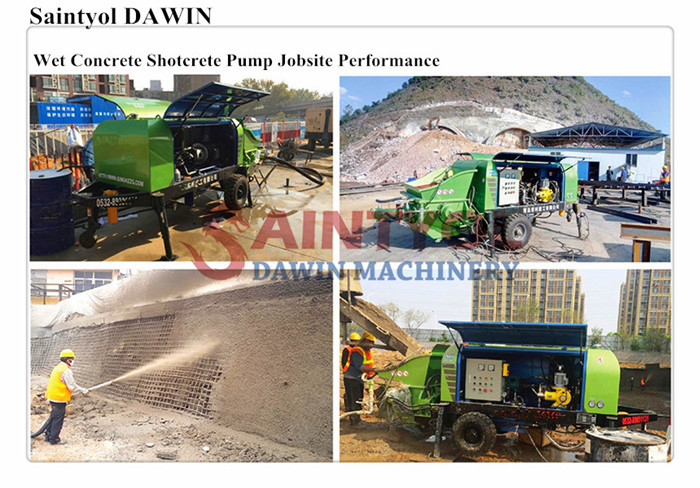

sourceSaintyol DAWIN Machinery Original

publisherJenny

time2020/03/31

- First, the preparation work of the hydraulic wet concrete spraying machine before starting

1. First, fix the hydraulic wet concrete spraying machine on a solid foundation. The spraying pipe must be reinforced and the pipeline must be installed properly without leakage.

2. Connect the three-phase power supply and check the lubricating oil level.

First, the preparation work of the hydraulic wet concrete spray machine before starting

1. First, fix the hydraulic wet concrete spraying machine on a solid foundation. The spraying pipe must be reinforced and the pipeline must be installed properly without leakage.

2. Connect the three-phase power supply and check the lubricating oil level.

3. Check that there is no foreign matter movement in the hopper and various moving parts, and that there is no looseness of each part. If it is loose, it must be reinforced and the hopper screen must be tightly covered.

4. Check the electrical control system, keep all switches in the off position, and check that the electrical appliances are not abnormally loose.

5.Close the lower right air switch in the electric control box, and close the two upper left air switches, check the power voltage, it must not be lower than 380V ± 10%, turn on the emergency stop button, start the control power start button, the button light is on Then, press the motor stop button with the left hand, press the motor start button with the right hand, click the motor start button with the right hand, and immediately press the motor stop button with the left hand (the startup time must not exceed 5 seconds). Observe the rotation of the motor. If the direction of the motor is reversed, replace the two power wires arbitrarily, and then test again to make the motor rotate forward. If the motor rotates backward, the pump will be damaged.

Second, the hydraulic wet spraying machine sprayed concrete operation process

1. Start the hydraulic wet spraying machine, fill the hopper with water, and press the positive pump start button to pump 1-2 buckets of water. After the pump is finished, stop the positive pump and immediately pour in a slightly thicker mortar and wait for stirring. After the uniformity, press the positive pump start button, after pumping 2-3 buckets of mortar, you can put in the appropriate concrete and start pumping. Note that when spraying concrete, the concrete in the hopper must not be lower than the mixing shaft, so as to avoid injury from concrete splashing from the hopper.

2. During the sprayed concrete operation, always check the cooling water source and oil temperature gauge. The oil level must not be higher than 50 ° C. The pressure gauges and voltage and current gauges should work normally. The oil temperature is too high to speed up the cooling water flow rate. When the pointer reaches the red area, it should be removed and washed with gasoline. When the pressure gauge of the return filter element reaches the red area, the filter element should be replaced.

3. During work, if there is an emergency, you should not hesitate to turn off the emergency stop button, and then restart the machine after the fault is removed. When restarting, ensure that the switches are in the on position. If it is determined that the failure cannot be resolved within 1 hour, the concrete in the hopper, the conveying cylinder, the S pipe and the pump pipe must be cleaned.

4. If there is a blocked pipe during work, you can reverse pump 1-2 times, and then turn on the positive pump. Repeat this two times. Generally, the blocked pipe can be ruled out. If it still cannot be ruled out, stop the positive pump and remove the blocked pump pipe. After cleaning, spray the concrete.

Three, precautions for safe operation of hydraulic wet concrete spraying machine

1. Add enough water to the hopper, open the positive pump to clean the concrete in the tank, then open the valve at the bottom of the hopper, and clean the concrete in the hopper with water; open the reverse pump, and add clean water from the outlet to continue cleaning until the hopper flows Until the water is clear, close the valve at the bottom of the hopper and remove the hose at the front of the pump tube.

2. Add sufficient water to the hopper and ensure that the water source is sufficient. Turn on the positive pump to start water washing. During the washing process, do not stop the pump or the reverse pump. Open the valve under the hopper, and then open the reverse pump. .

3. Turn on the forward or reverse pump, let the pump run dry for 10 minutes, and check the agitator bearings and S-tube size bearings until the lubricant is discharged.

4. Drain the water in the water tank, clean the water tank, turn off the cooling water source, check whether there is concrete in the hopper, S pipe, and conveying tank, and clean it up in time.